Stepper Motors vs. Servo Motors: Which is Better?

Stepper Motors vs. Servo Motors: Which is Better?

Stepper motors and servo motors are two of the most commonly used types of motors in industrial and robotic applications. Both types of motors have unique features and advantages, and choosing the right type of motor for your application can be a critical decision. In this article, we will compare stepper motors and servo motors and discuss their respective strengths and weaknesses.

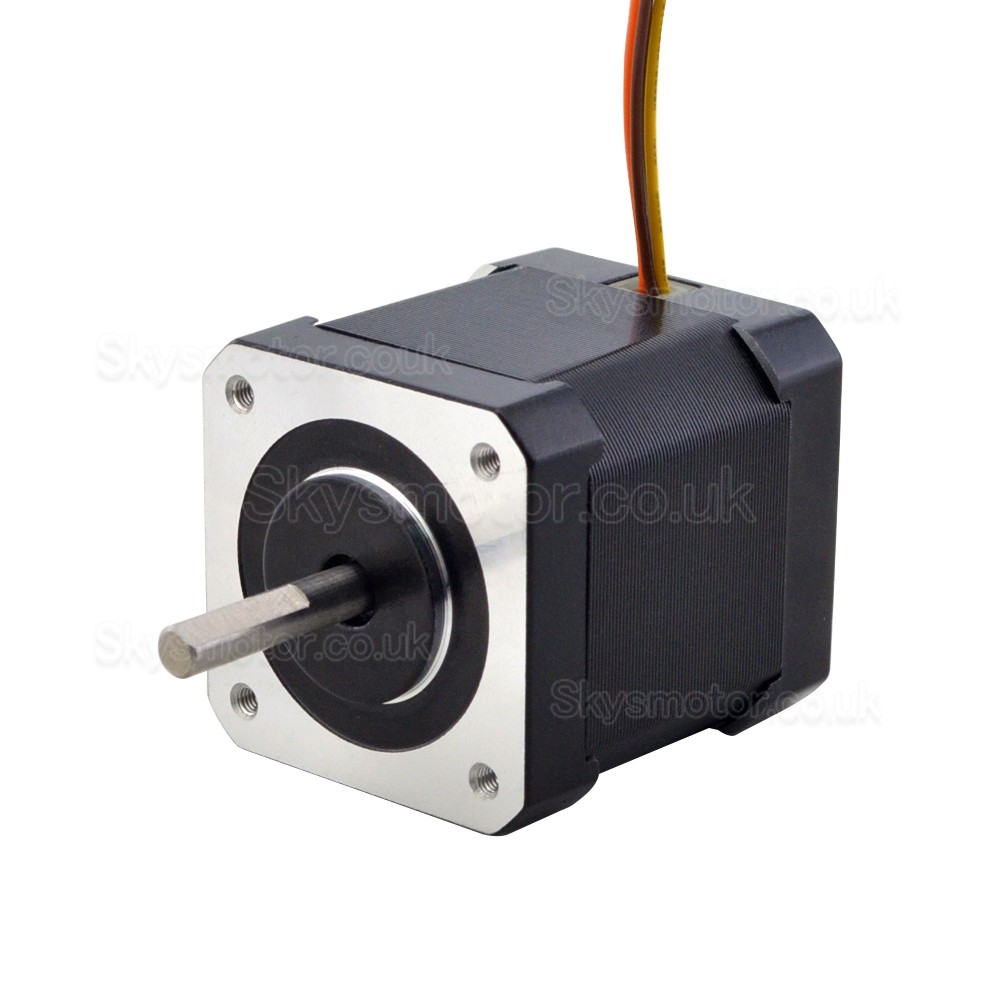

Stepper Motors

Stepper motors are DC motors that move in discrete steps. They are designed to move in small, precise increments, making them ideal for applications that require high accuracy and repeatability. Stepper motors can be easily controlled using a microcontroller or a specialized stepper motor driver, which generates the sequence of current pulses required to move the motor in small steps.

One of the main advantages of stepper motors is their simplicity. Stepper motors have a simple construction, with no brushes or commutators, and can be easily controlled using a basic driver circuit. They also have a high torque-to-inertia ratio, which means that they can move heavy loads with high precision and accuracy.

However, stepper motors also have some disadvantages. They can be prone to resonance and vibration, which can affect their accuracy and stability. Stepper motors also have a limited speed range, and their speed is dependent on the frequency of the current pulses applied to the motor.

Servo Motors

Servo motors are DC motors that use feedback control to achieve precise positioning and motion control. They are designed to provide high torque at low speeds and can be used in a wide range of applications, from industrial machinery to robotics.

One of the main advantages of servo motors is their high accuracy and precision. Servo motors use feedback control to maintain a specific position or speed, which means that they are highly accurate and can maintain their position even under varying loads and conditions. They also have a wider range of speeds and can operate at high speeds without losing accuracy.

However, servo motors also have some disadvantages. They are more complex than stepper motors and require a more advanced control system to operate. They also have a lower torque-to-inertia ratio than stepper motors, which means that they may not be suitable for applications that require high torque at low speeds.

Which is Better: Stepper Motors or Servo Motors?

The answer to this question depends on the specific requirements of your application. If your application requires high accuracy and repeatability, a stepper motor may be the better choice. Stepper motors are also simpler and more cost-effective than servo motors, making them a good choice for applications with a limited budget.

However, if your application requires high-speed operation and precise motion control, a servo motor may be the better choice. Servo motors are also more versatile than stepper motors and can be used in a wider range of applications.

In general, servo motors are more complex and expensive than stepper motors, but they offer higher performance and greater flexibility. Stepper motors are simpler and more cost-effective, but they may not be suitable for applications that require high-speed operation or precise motion control.