What is the difference between NEMA 17 and 23?

What is the difference between NEMA 17 and 23?

NEMA 17 and NEMA 23 are two of the most commonly used stepper motor sizes in industrial and automation applications. While both sizes of motors share some similarities, there are also several key differences that make them better suited for different types of applications. In this article, we will explore the main differences between NEMA 17 and NEMA 23 stepper motors.

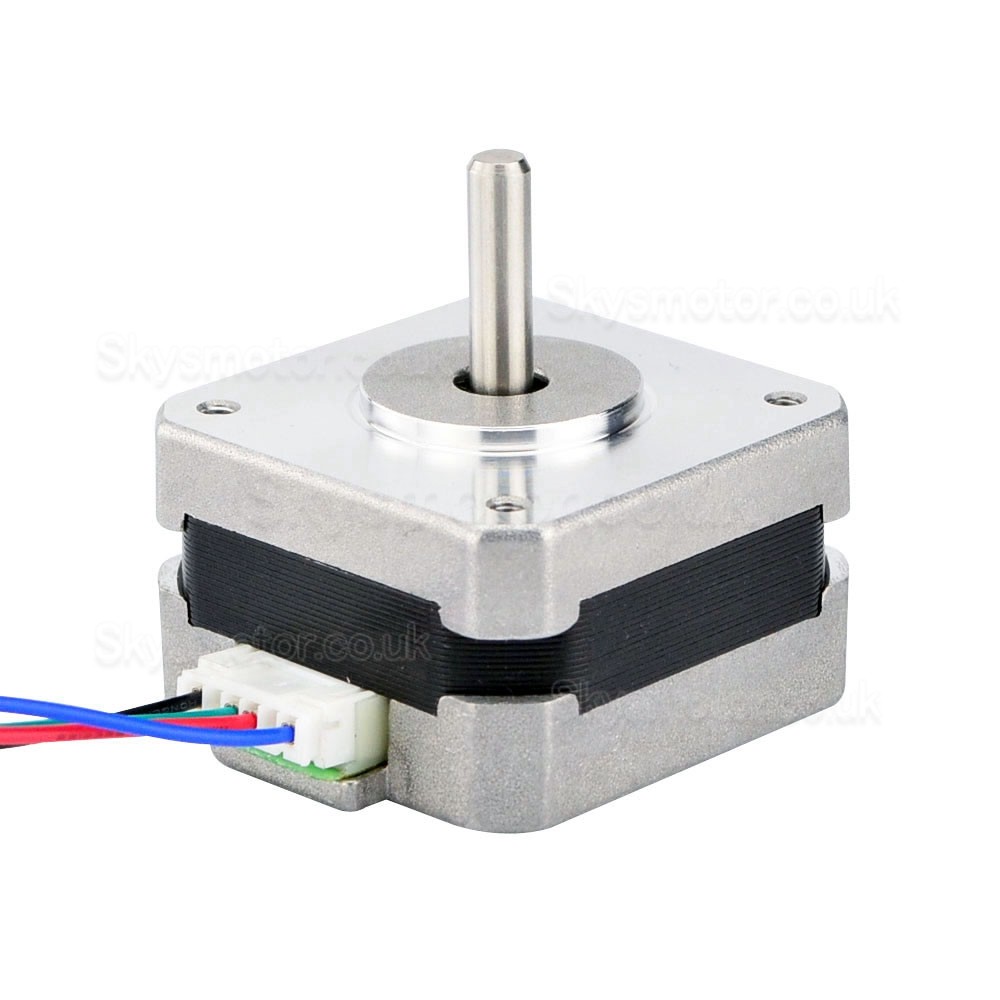

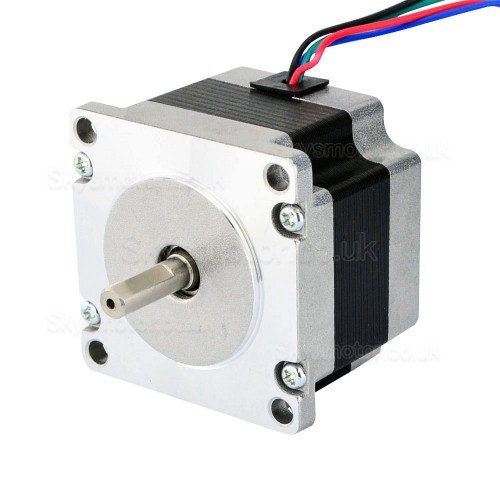

Size and weight

The most obvious difference between NEMA 17 and NEMA 23 stepper motors is their size and weight. NEMA 17 motors have a standard faceplate of 1.7 inches (42.3 mm) square and a length of 1.18 inches (30 mm). NEMA 23 motors have a standard faceplate of 2.3 inches (57.0 mm) square and a length of 2.2 inches (56 mm). As a result, NEMA 23 motors are larger and heavier than NEMA 17 motors.

Torque

NEMA 23 stepper motors generally have a higher torque than NEMA 17 motors. This is because NEMA 23 motors have a larger rotor and stator, which allows for more powerful magnetic field interactions. NEMA 23 motors are therefore better suited for applications that require high torque and high precision, such as CNC machines, robotics, and automation systems.

Speed

NEMA 17 motors are generally better suited for high-speed applications than NEMA 23 motors. This is because NEMA 17 motors have a smaller rotor and stator, which allows for faster rotation and less inertia. NEMA 17 motors are therefore commonly used in applications such as 3D printers, scanners, and engraving machines that require high speed and precision.

Power consumption

NEMA 23 motors generally consume more power than NEMA 17 motors due to their larger size and higher torque. This means that NEMA 23 motors may require larger power supplies and more robust wiring than NEMA 17 motors. However, the power consumption of both types of motors can vary depending on the specific application and the motor driver used to control them.

Step angle

The step angle of a stepper motor refers to the angle that the motor rotates with each step. NEMA 17 motors typically have a step angle of 1.8 degrees, while NEMA 23 motors typically have a step angle of 1.8 or 0.9 degrees. A smaller step angle allows for more precise control over the motor's movement, but it also requires more steps to complete a full rotation.

Price

NEMA 23 motors are generally more expensive than NEMA 17 motors due to their larger size, higher torque, and greater power consumption. However, the price of both types of motors can vary widely depending on the specific manufacturer, model, and features.