What is a BLDC motor ? Which is better BLDC or DC motor?

What is a BLDC motor ? Which is better BLDC or DC motor?

What is a BLDC motor ?

A BLDC motor, or a Brushless DC motor, is a type of electric motor that operates using direct current (DC) power. It is a more advanced version of the traditional brushed DC motor, which has been used in various applications for many years. However, unlike brushed DC motors, BLDC motors do not use brushes for the transfer of power from the stator to the rotor. Instead, they use electronic commutation to control the motor's speed and direction of rotation.

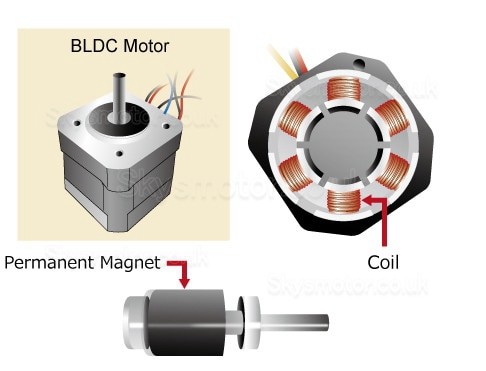

BLDC motors are composed of a stator, rotor, and permanent magnets. The stator is the stationary part of the motor and contains the windings that generate the magnetic field. The rotor is the rotating part of the motor and contains the permanent magnets. The permanent magnets on the rotor interact with the magnetic field generated by the windings on the stator to create torque and rotation.

The electronic commutation of a BLDC motor is achieved using a controller that controls the switching of the current to the windings. The controller uses feedback from sensors, such as Hall-effect sensors, to determine the position of the rotor and commutate the motor at the appropriate time. The commutation of the motor is done in a sequence to ensure that the magnetic field generated by the windings is always in the correct position to interact with the permanent magnets on the rotor.

Which is better BLDC or DC motor?

When it comes to choosing between a BLDC (Brushless DC) motor and a traditional DC (Direct Current) motor, there are several factors to consider. Both types of motors have their own strengths and weaknesses, and the best choice depends on the specific application and requirements.

One of the main advantages of DC motors is their simplicity. They have a relatively simple design and are easy to control. They are also less expensive than BLDC motors, which can be a significant factor in some applications. DC motors are widely used in applications that require low to medium power output, such as small appliances, toys, and automotive applications.

However, when it comes to high-performance applications, BLDC motors are often the better choice. One of the main advantages of BLDC motors is their efficiency. Since there are no brushes to create friction and wear out, BLDC motors have a longer lifespan and require less maintenance than DC motors. They also have a higher power-to-weight ratio and can operate at higher speeds than DC motors. This makes them ideal for applications that require high power output and precise control, such as electric vehicles, industrial equipment, and robotics.

Another advantage of BLDC motors is their ability to provide precise control over the speed and torque of the motor. This is achieved through electronic commutation, which allows for smooth and precise control over the motor's speed and direction of rotation. DC motors, on the other hand, rely on mechanical commutation, which can result in less precise control over the motor's speed and direction.

BLDC motors also have a lower noise and vibration level than DC motors. This is due to the absence of brushes, which can create noise and vibration as they make contact with the commutator. This makes BLDC motors ideal for applications that require low noise and vibration levels, such as medical equipment and audio equipment.

________________________________________________________

skysmotor.co.uk is a professional online supplier of closed loop stepper motor nema 23 and closed loop stepper motor nema 34. We offer competitive prices and efficient

services to our customers.