How is the waterproof level of the stepper motor divided?

How is the waterproof level of the stepper motor divided?

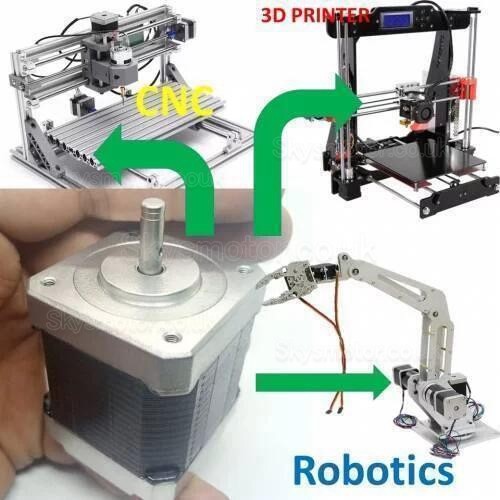

Stepper motors are widely used in various applications, such as robotics, CNC machines, 3D printers, and surveillance cameras, due to their precise control over position, velocity, and acceleration. However, in some applications, stepper motors may be exposed to water or other liquids, which can cause damage or malfunction. Therefore, it is essential to design and select stepper motors with appropriate waterproof levels. In this article, we will discuss the technology behind stepper motor waterproofing and the waterproof levels commonly used in the industry.

Stepper Motor Waterproofing

Stepper motors are typically not waterproof by nature, as they have exposed windings and bearings that can be damaged by moisture or liquids. Therefore, to make a stepper motor waterproof, it requires additional waterproofing measures to be taken during the motor's design and manufacturing process. Some of the common waterproofing measures include:

Encapsulation: The motor's windings and electronic components are encapsulated with a waterproofing material, such as epoxy or silicone. This provides a barrier against moisture and liquids and protects the internal components from corrosion and short circuits.

Sealing: The motor's bearings and shaft are sealed with waterproof seals or gaskets to prevent water or other liquids from entering the motor's internal components. The seals or gaskets are typically made of rubber or other elastomers that can withstand exposure to water and chemicals.

Coating: The motor's external surfaces are coated with a waterproofing material, such as polyurethane or Parylene, to prevent water or other liquids from penetrating the motor's housing. The coating also provides additional protection against abrasion, corrosion, and UV radiation.

Waterproof Levels

The waterproof level of a stepper motor refers to its ability to resist the ingress of water or other liquids. The waterproof level is typically represented by an IP (Ingress Protection) rating, which is defined by the International Electrotechnical Commission (IEC). The IP rating consists of two digits, where the first digit indicates the degree of protection against solid objects, and the second digit indicates the degree of protection against liquids.

The following table shows the IP rating system and the corresponding degree of protection against water:

IP Rating Protection against water

IPX1 Dripping water

IPX2 Dripping water (15° tilt)

IPX3 Spraying water

IPX4 Splashing water

IPX5 Water jets

IPX6 Powerful water jets

IPX7 Immersion up to 1 meter

IPX8 Immersion beyond 1 meter

For example, an IPX7-rated stepper motor can withstand immersion in water for up to 1 meter without damage or malfunction.

Factors Affecting Stepper Motor Waterproofing

Several factors can affect the waterproofing of a stepper motor. These factors include:

Material Selection: The choice of materials used in the motor's construction and waterproofing measures can affect its ability to resist water or other liquids. Certain materials, such as stainless steel or ceramic, are more resistant to corrosion and moisture than others.

Environmental Factors: The environment in which the motor operates, such as temperature, humidity, and exposure to chemicals, can affect its waterproofing. Stepper motors used in harsh environments, such as marine or outdoor applications, may require higher waterproof levels than those used in indoor applications.

Manufacturing Quality: The quality of the motor's manufacturing process can affect its waterproofing. Poorly sealed or encapsulated motors may allow water or other liquids to penetrate the internal components and cause damage or malfunction.

————————————————————————————————————————————

skysmotor.co.uk is a professional online supplier of stepper motor and servo motor. We offer competitive prices and efficient services to our customers.