The Role of Stepper Motors in CNC Automation

The Role of Stepper Motors in CNC Automation

In the world of computer numerical control (CNC) automation, stepper motors play a vital role in driving precise and controlled movements. These motors have revolutionized the manufacturing industry by enabling highly accurate and repeatable motion control in various CNC applications. This article aims to explore the significant role of stepper motors in CNC automation, highlighting their features, benefits, and applications.

Understanding Stepper Motors:

Stepper motors are electromechanical devices that convert digital pulses into mechanical shaft rotation. Unlike traditional motors, they move in discrete steps, making them ideal for applications that require precise positioning and control. Stepper motors consist of a rotor and stator, and they operate based on the principle of electromagnetism.

Features and Advantages of Stepper Motors:

High Positional Accuracy: Stepper motors offer exceptional positional accuracy, allowing them to position CNC tools or workpieces with great precision. This accuracy is achieved through the precise control of step sizes and the ability to maintain position without the need for feedback devices.

Open-Loop Control: Stepper motors operate in an open-loop system, meaning they do not require additional feedback devices like encoders. This simplifies the control system and reduces costs.

Cost-Effective: Stepper motors are generally more affordable compared to other motor types, making them an economical choice for CNC automation systems.

Torque at Low Speeds: Stepper motors provide high torque even at low speeds, ensuring that they can handle the required loads during CNC operations.

Easy to Interface: These motors can be easily controlled using digital signals, making them compatible with a wide range of CNC controllers and microcontrollers.

Applications of Stepper Motors in CNC Automation:

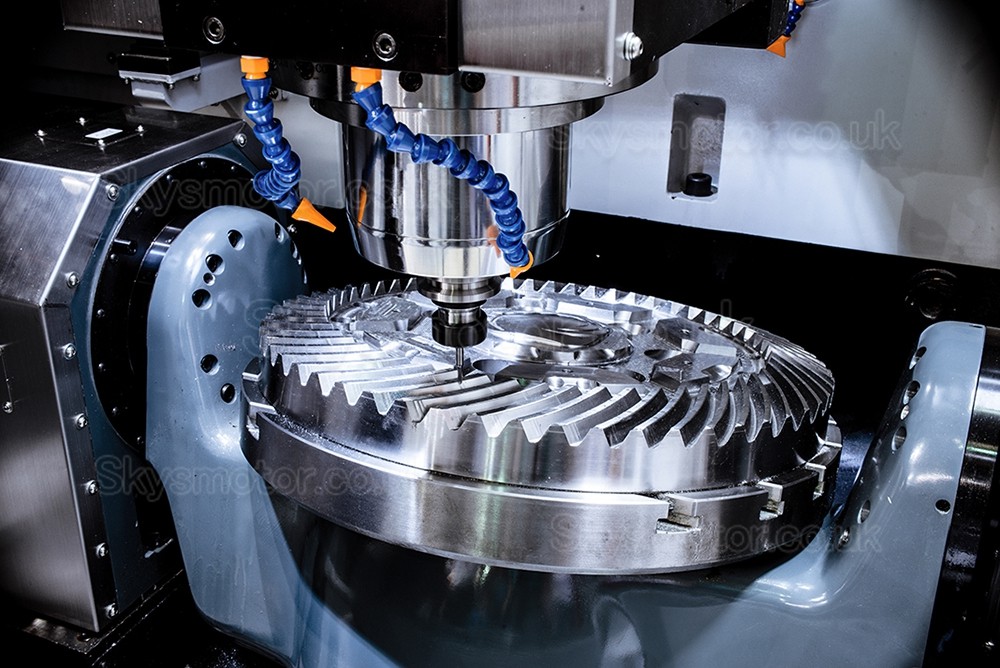

CNC Milling Machines: Stepper motors are commonly used in CNC milling machines to control the movement of the spindle, allowing for precise cutting, drilling, and shaping of materials.

CNC Routers: Stepper motors drive the motion of CNC router spindles, enabling the accurate carving, engraving, and shaping of various materials such as wood, plastic, and metal.

CNC 3D Printers: Stepper motors play a critical role in the precise movement of the print head and build platform in CNC 3D printers, ensuring accurate layering and intricate designs.

CNC Laser Cutters: Stepper motors control the movement of laser heads in CNC laser cutting machines, delivering precise and intricate cuts on various materials.

CNC Lathes: Stepper motors drive the tool movements in CNC lathes, allowing for precise turning, facing, and threading operations.

Considerations and Limitations:

Speed and Acceleration: Stepper motors have limitations in terms of maximum speed and acceleration due to their discrete step movement. High-speed applications may require other motor types, such as servo motors.

Power Consumption: Stepper motors can consume significant power, especially when holding a position. Proper power management and control are essential to optimize energy usage.

Heat Generation: Stepper motors can generate heat during operation, which may require additional cooling mechanisms to ensure optimal performance and longevity.

____________________________________________________________________________________

skysmotor.co.uk is a professional online supplier of Nema 17 Stepper Motor and Nema 23 Stepper Motor. We offer competitive prices and efficient services to our customers.