How to Choose a Linear Stepper Motor?

How to Choose a Linear Stepper Motor?

Linear stepper motors provide precise and controlled linear motion, making them suitable for a wide range of applications such as CNC machines, 3D printers, robotics, and automation systems. Selecting the right linear stepper motor is crucial to ensure optimal performance and efficiency in your specific application. This article will guide you through the key factors to consider when choosing a linear stepper motor.

Determine Your Application Requirements:

Before delving into the technical specifications, it is essential to have a clear understanding of your application requirements. Ask yourself the following questions:

a. What is the required linear travel distance?

b. What is the desired speed and acceleration?

c. What is the load capacity and payload weight?

d. What level of precision and repeatability is necessary?

e. Are there any environmental considerations such as temperature, humidity, or dust?

Types of Linear Stepper Motors:

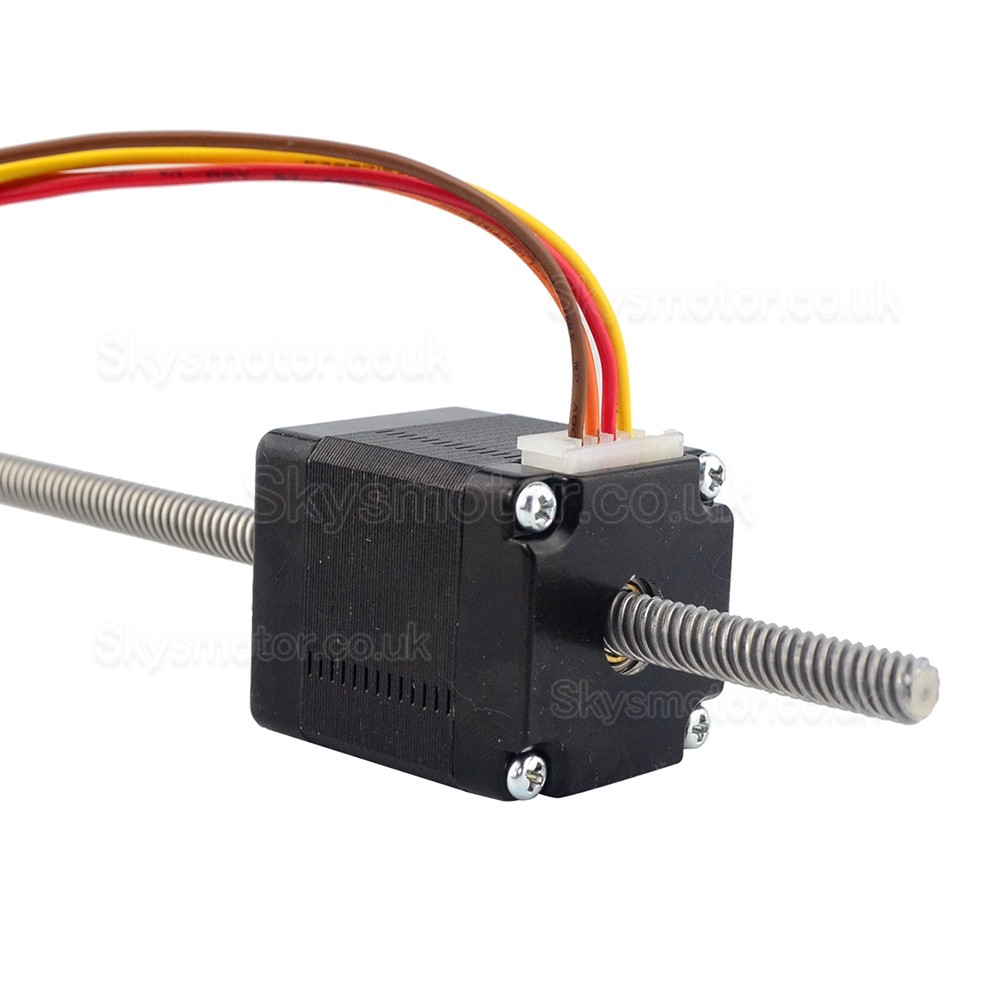

There are primarily two types of linear stepper motors: captive and non-captive. Understanding the differences between these types will help you choose the most suitable option for your application.

a. Captive Linear Stepper Motors: These motors have a fixed shaft and are suitable for applications where the load is directly attached to the motor. They provide high thrust force and are ideal for applications requiring compact designs and precise positioning.

b. Non-Captive Linear Stepper Motors: Non-captive motors have a separate load-carrying mechanism, allowing independent movement of the load. They offer higher linear travel distances and are suitable for applications requiring long strokes or where the load needs to move independently from the motor.

Consider Linear Stepper Motor Specifications:

Once you have determined the type of linear stepper motor that suits your application, consider the following specifications:

a. Stroke Length: The stroke length determines the maximum linear travel distance of the motor. Choose a motor with a stroke length that meets your application requirements. Consider factors such as available space and the required range of motion.

b. Force and Load Capacity: Evaluate the force and load capacity of the linear stepper motor. The force rating indicates the maximum thrust the motor can generate, while the load capacity specifies the maximum weight the motor can handle. Ensure that the motor's force and load capacity are sufficient to handle your application's requirements.

c. Speed and Acceleration: Consider the speed and acceleration capabilities of the linear stepper motor. These specifications determine the motor's ability to move the load quickly and smoothly. Select a motor that can achieve the desired speed and acceleration for your application.

d. Resolution and Accuracy: The resolution and accuracy of the linear stepper motor impact the precision of the linear motion. Higher resolution and accuracy allow for finer positioning and improved overall performance. Consider the required level of precision for your application and choose a motor that meets those requirements.

Evaluate Motor Control and Feedback Options:

Linear stepper motors can be controlled using various methods, including open-loop and closed-loop systems. Open-loop systems operate based on predetermined steps without feedback, while closed-loop systems utilize position feedback to ensure precise positioning.

Consider the control system that best suits your application. If high precision and accuracy are crucial, a closed-loop system with position feedback, such as encoders, may be preferred. However, open-loop systems may suffice for applications where precision requirements are not as strict.

Quality and Reliability:

Choose a linear stepper motor from a reputable manufacturer known for producing high-quality and reliable products. Look for motors that have undergone thorough testing and have a track record of performance in similar applications. Read customer reviews and seek recommendations from industry experts to ensure you select a motor that will provide long-term reliability.