NEMA 23 Stepper Motors VS NEMA 24 Stepper Motors

What is the Difference between NEMA 23 and NEMA 24 Stepper Motors?

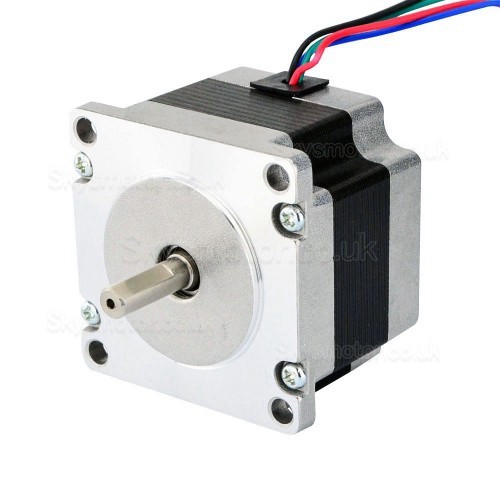

Stepper motors are extensively used in the domain of robotics, CNC machines, and other automated systems due to their precise control and movement capabilities. Among the various categories of stepper motors available on the market, NEMA 23 and NEMA 24 stepper motors are two popular types. Despite their similarities, they also possess distinct differences that can influence their application in various scenarios. This article aims to elucidate these differences to help users choose the right stepper motor for their needs.

Overview of NEMA 23 and NEMA 24 Stepper Motors

NEMA is an acronym for the National Electrical Manufacturers Association, an organization that sets the standards for the manufacture of electrical equipment, including stepper motors. The numbers 23 and 24 following the NEMA abbreviation refer to the faceplate dimensions of the motors in tenths of inches. Therefore, a NEMA 23 motor has a faceplate approximately 2.3 inches (58.4mm) square, while a NEMA 24 motor has a faceplate that is around 2.4 inches (60.96mm) square.

NEMA 23 motors are versatile, with a wide range of applications. They are powerful enough for medium-demand tasks while maintaining a compact size. You can commonly find them in CNC routers, smaller milling machines, and large 3D printers. They offer a good balance between size, cost, and power, which makes them a popular choice in many industries.

NEMA 24 Stepper Motors

NEMA 24 motors are slightly larger and more powerful than NEMA 23 motors. As such, they are better suited to applications that require more torque. These motors are typically used in larger CNC machinery, industrial applications, and robotics where high precision and power are necessary.

Key Differences between NEMA 23 and NEMA 24 Stepper Motors

While both NEMA 23 and NEMA 24 motors are used in similar applications, there are crucial differences between them in terms of size, power, and torque.

Size

The most obvious difference between the two types of motors is their size. NEMA 24 motors are slightly larger than NEMA 23 motors. This size difference may seem negligible, but it can have significant implications for the motor's mounting and the overall size of the device in which it is installed.

Power and Torque

NEMA 24 motors are generally more powerful and produce more torque than NEMA 23 motors. This is due to the larger size of the motor, which allows for more windings or larger ones, resulting in higher power output and torque. However, this increased power comes at the cost of greater power consumption and potentially more heat production.