400W/600W/750W/1000W AC Servo Motor & Driver Kit 110V / 220V 1.27Nm-3.8Nm For CNC And PLC Systems

- 6% Off On Total Order Amount!

- Enjoy Discount at Checkout! No Need Coupon Code!

- Valid Till April 26th,2025

400W/600W/750W/1000W AC Servo Motor & Driver Kit 110V / 220V 1.27Nm-3.8Nm For CNC And PLC Systems

Description:

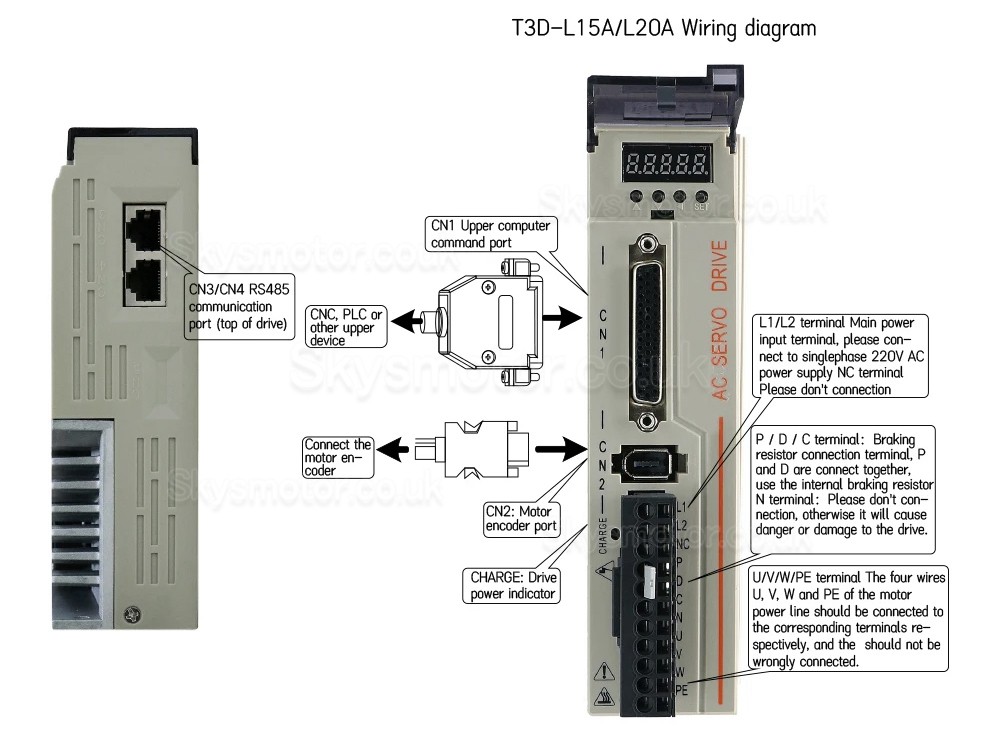

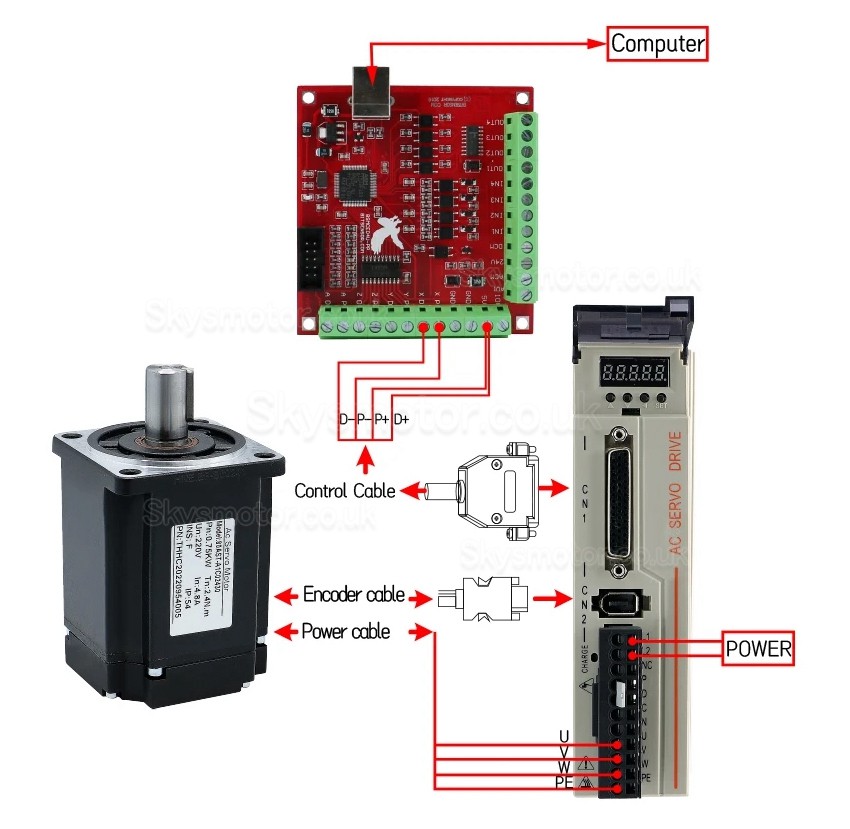

1: Support pulse (5V or 24V pulse signal), analog quantity (0-10V), modbus RS485 control

2: Supports CNC and PLC systems

3: To connect to a 24V pulse signal, two 2K 1/4W resistors need to be connected in series for P+and D+, otherwise the driver will burn out

4: The motor with brakes needs to be connected to a 24V external power supply and relay

5: Power on settings

Change P-036 to 1 (opposite direction) 0 (positive direction) motor direction conversion parameter

Change P-098 to 1 (internal enable) 0 (external enable)

The larger the parameter of P-029 electronic gear ratio, the faster the speed

Long press the confirm button on E-SEF to display DONE saved successfully. After setting all parameters, power off and restart.

Packing list:

1* Servo Motor ( 17 bit absolute )

1* AC Driver

1* 3Meter Encoder Cable + Power Cable

1* Control Signal Cable

2* 2K 1/4W resistance

1* RS485 Cable

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

| Technical Specifications | ||||

| Rated Voltage (V) | 220 | 220 | 220 | 220 |

| Rated Power (W) | 400 | 600 | 750 | 1000 |

| Rotor pole pairs (P) | 5 | 5 | 5 | 5 |

| Rated Torque ( Nm ) | 1.27 | 1.91 | 2.4 | 3.8 |

| Instantaneous max torque (Nm ) | 3.82 | 5.73 | 7.2 | 11.4 |

| Rated Speed / Max Speed (rpm) | 3000/6000 | 3000/6000 | 3000/5000 | 2500/3000 |

| Rated Current ( A ) | 2.8±10% | 4±10% | 4.8±10% | |

| Instantaneous Max Current (A) | 8.4±10% | 12±10% | 14.4±10% | |

| Moment Coefficient (Nm/A ) | 0.42±10% | 0.54±10% | 0.5±10% | 0.93±10% |

| Back EMF Coefficient ( X10 V/rpm) | 27.5±10% | 32.5±% | 33.2±10% | 56±10% |

| >Resistance (Ω ) | 3±10% ( 20℃ ) | 3.2± 10%(20 ℃) | 1.6 ± 10%(20 ℃) | 3±10%(20℃) |

| Inductance ( mH) | 7.8±20% ( 20℃ ) | 8.4±20% ( 20℃) | 9.5±20% (20℃) | 19±20% (20℃) |

| Moment of inertia ( X10V/rpm ) | 0.68 [0.73] ± 10% | 0.82[1.7] ± 10% | 1.72 [1.77]± 10% | 2.4[2.45]±10% |

| Max radial load ( N ) | 245 | 392 | ||

| Max axial load ( N ) | 74 | 147 | ||

| Weight ( KG) | 1.22 [1.65]± 10% | 1.4[1.7]±10% | 2.2[3]±10% | 2.71[3.36]±10% |

| Encoder Resolution | 10000ppr | |||

| Protection Structure | IP65 | |||

| Insulation class | F | |||

| Insulation Resistance | More than 20m Ω DC500V | |||

| Insulation Withstand voltage | AC 1500V 1minutes | |||

| Vibration Level | Rated A for operation | |||

| Turn Around | Forward turn command,viewed from load sid, counterclockwise (CCW) | |||

| Surroundings | Temperature -20℃ ~ 40 ℃, humidity 20% ~ 80% RH ( no condensation ) , altitude below 1000 | |||

| Temperature - 20℃ ~ 60℃, (no freezing) humidity 20% ~ 80% RH (no condensation) | ||||

| Impact Strength | 98m/S ² | |||

| Vibration Resistance | 49m/S ² | |||

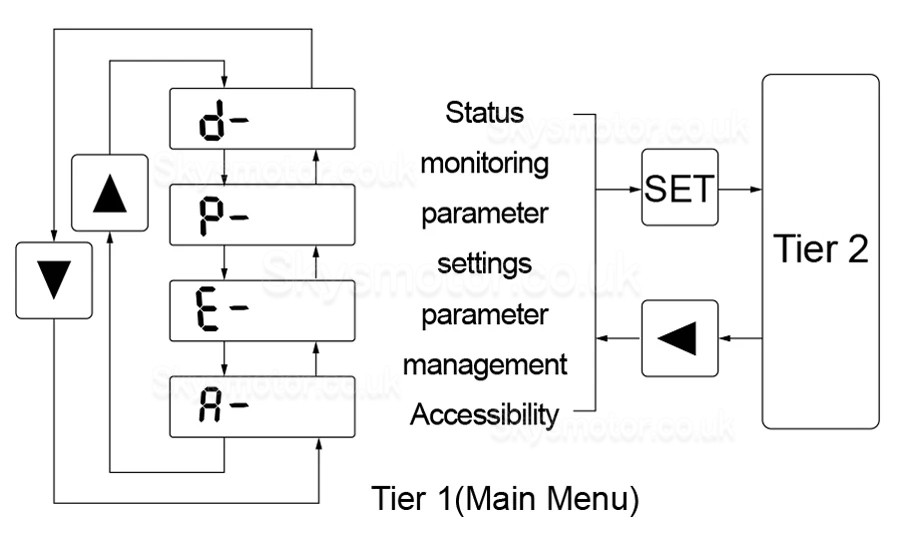

| Symbol | Name | Function |

| POW | Power Light (none) |

The decimal point of the second digital bube from the left lights up to indicate that the servo is under voltage |

| RUN | Runing light (none) |

The decinal point of the first digital tube from the left lights up to indicate that the servo is enabled |

| ▲ | Add key | Increase the serial number of value, long press has repeat effect |

| ▼ | Decrease Key | Decrease the serial number of value,long preass haas repeat effect |

| ◀ | Exit Key | Menu exit, operation cancelled, |

| SET | Enter | Menu Entry,parameter modification confirmation or operation confirmation |

Set After Power on:

Find P-098 and change it to 1

Find the E-SEF, press and hold the confirmation key until it shows DONE. then the parameters has been saved successfully. After all parameters are set, power off and restart.

Common parameters:

P-036 is changed to 1 (reverse direction) 0 (positive direction) motor direction conversion parameter. The default is 1 reverse direction

P-029 (electronic gear ratio numerator) is 1 by default, the higher the value, the faster the speed

(The above parameters are general setting parameters. If you need to modify other parameters, please refer to the manual or contact the technical/sales personnel)

The following parameters are rigid adjustment parameters. No adjustment is needed if the equipment is OK

P-005 (Speed ring rigidity)

P-009 (Position ring rigidity)

P-006 (generally, the maximum setting is about 100)

P-019 (generally, the maximum setting is about 300)

| Servo Motor Specification | |

|---|---|

| Rated Power(W) | 400 / 600 / 750 / 1000 |

| Input Voltage(V) | 220 |

| Rated Speed(rpm) | 3000 / 2500 |

| Rated Torque(Nm) | 1.27 / 1.91 / 2.4 / 3.8 |

| Peak Speed(rpm) | 3.82 |

| Peak Torque(Nm) | 5.73 / 7.2 / 11.4 |

| With Brake | With brake |

| Physical Specification | |

| Body Length(mm) | 96 / 114 / 106 / 115 |

| Shaft Diameter(mm) | 14 / 19 |

| Shaft Length(mm) | 25 |

| Shaft Type | Keyway |

| Weight(g) | 1660 / 1700 / 3000 / 3360 |

クレジットカード決済

クレジットカード決済 PayPal

PayPal